Making mallets is very slow work. (Video)

First, we buy 50 (fifty) 30-mm bouncyballs …

Then we drill 11/64-inch holes in them …

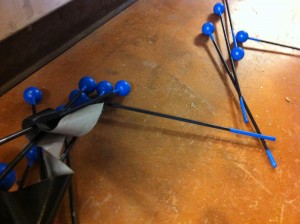

And stick them onto 16-inch-long rods of 3/8-inch (and 1/4-inch) fiberglass, procured from a Max-Gain Systems, a very friendly radio-antenna-supply house in Georgia (thanks, Google) …

After dipping (about which, more below) the blue ones look like this …

We make the soft mallets blue (to tell them apart from the hard, yellow sticks). Soft mallets work best on the lowest keys, where the soft hit of the bouncyball heads brings out the lower dominant tones of the metal. Hit those low keys with the hard sticks and all you hear is nasty overtones rather than the dominants.

Likewise, using the soft, blue mallets on the shorter upper keys and the disc gongs on XyloVan’s doors results in a muted tone. Those keys like to be hammered with the hard yellow sticks. Someday we’ll have to post a demo video to demonstrate. Either that, or you’ll have to find XyloVan and try it out yourself. ;D

We use PlastiDip, a fast-drying liquid vinyl compound …

The 3/8 “hard” sticks have no balls (yes, that’s a straight line) and so take multiple dips so that we build up a nice, reslient tip …

As you’ll see in the (video), you have to wait a few seconds after each dip to let the excess drain off so that you don’t get drips or – even worse – the situation where the vinyl compound skins over and then sloughs off, taking most of the remaining liquid with it.

We stick them up to long strips of duct tape, which hold them long enough to dry …

And then eventually fail, dropping the dried sticks to the floor overnight.