I have to finish this by 7/30, since other obligations will prevent me from working on it much more until the week before Burning Man.

So I’ve spent the past week solid (nearly) chopping through task after task. At right are the steel-conduit outriggers I installed at the top of the framework – this will give me something to hang light-bars and speakers from.

Here are the lightbars, cut from 1x4s and painted with a dull-silver hammertone paint.

Here are the lightbars, cut from 1x4s and painted with a dull-silver hammertone paint.

David (our architect) spent much of last night using a cutting wheel (courtesy of the Disco Kremlin crew – thanks!) to cut out cloud shapes from the sheets of perforated steel that is usually used in plastering walls.

David (our architect) spent much of last night using a cutting wheel (courtesy of the Disco Kremlin crew – thanks!) to cut out cloud shapes from the sheets of perforated steel that is usually used in plastering walls.

These will be screwed to the crown rail around the top of the pianos once we get to the playa.

Here’s another shot of the work, with the camera flash turned off. Much better.

Here’s another shot of the work, with the camera flash turned off. Much better.

Earlier, my son had silver-painted all the 1×2 pine furring strips we had, which I tacked up as proof-of-concept for a design layer on the pianos’ top edge. We’ll be getting more of these and painting them the week before the burn so that we can batten down the top and bottom edges of JANUS’ skin.

Earlier, my son had silver-painted all the 1×2 pine furring strips we had, which I tacked up as proof-of-concept for a design layer on the pianos’ top edge. We’ll be getting more of these and painting them the week before the burn so that we can batten down the top and bottom edges of JANUS’ skin.

We then gave JANUS a healthy bath of Flame-X – a fire retardant chemical to protect the otherwise pretty-flammable cotton from following the path of combustion.

We then gave JANUS a healthy bath of Flame-X – a fire retardant chemical to protect the otherwise pretty-flammable cotton from following the path of combustion.

Then David and I stood back for a minute to admire our handiwork …

Then David and I stood back for a minute to admire our handiwork …

… and started the teardown. We basically un-built JANUS – stripping off the canvas skins, unscrewing all the framing, unbolting the foundational lumber, and then removing the hinge-pinned profiles. It took about two hours.

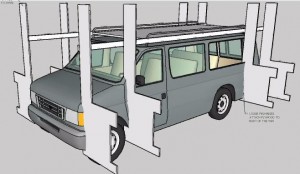

David peeled off for bed at around 1 a.m. this morning, and I finished up, stacking everything as neatly as I could on top of the van. I got done around 4 a.m., came home to catch a few hours sleep, and returned with a new set of come-along straps from Pep Boys to secure the load.

There’s still much to do, but we’ll attend to that the week before the burn – and on the playa:

– Wiring the light-bars

– Re-wiring XyloVan’s roof to fit JANUS’ light- and speaker-positions

– Sewing pipe sleeves into the rear fabric panels

– Acquiring 170 linear feet of furring strips for battens – and painting them silver

But for now, JANUS is complete.

I just want to give thanks here to some good friends, old and new, without whom this would never have happened – or would have ended badly:

– Dave LaFontaine, John Amussen and Alan Hagman for excellent company and assistance

– The crew next door building the Disco Kremlin bus – Mac, Bernie and Tina, for being endlessly helpful, friendly and generous. Thanks for the use of all the tools and materials that helped us solve more than a couple show-stoppers

– David Hoffman, who took my half-assed architectural ideas, and made my mutant vehicle design concept into a portable, reusable, customizable and easily-assembled reality.

– My kids, Biomass and Hitgirl, for lending a hand when it was needed most, and finally my long-suffering wife, Kristina, whose encouragement, support and patronage made it happen.

We built an art car in 30 days or less. Now all we have to do is get it to the playa.