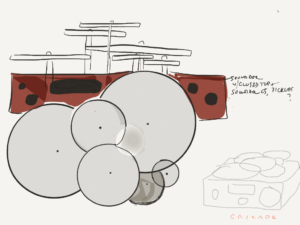

Long, long ago, in a city far, far away (2010, Los Angeles), I made this crazy thing with the help of my loving and endlessly tolerant family.

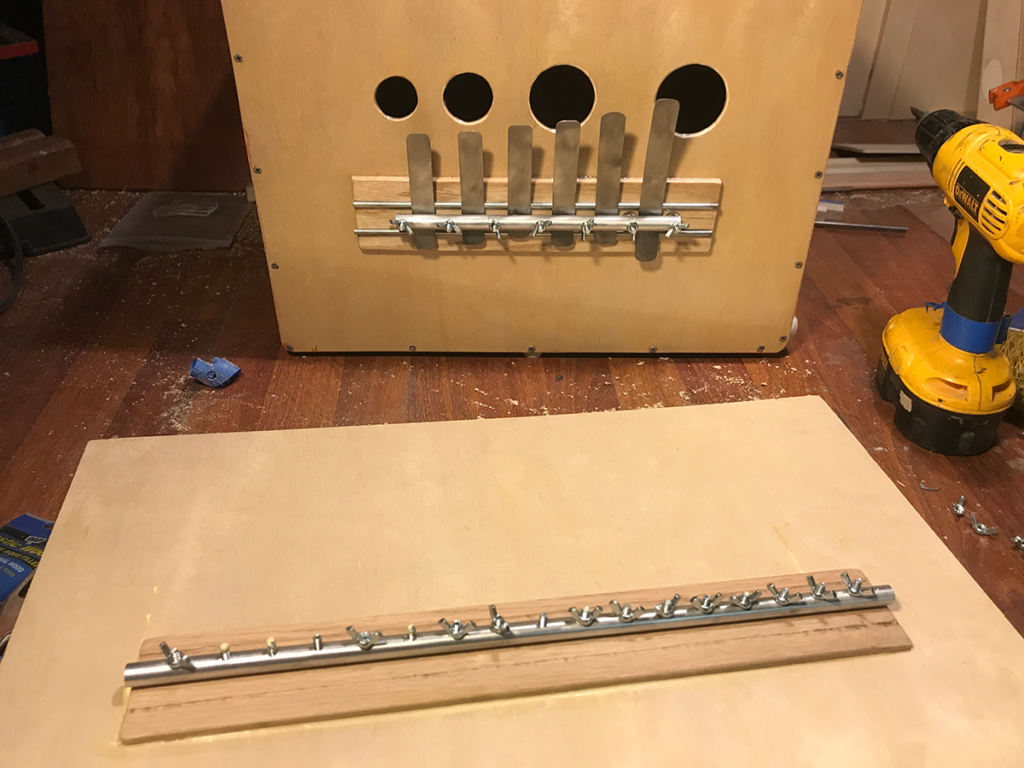

XyloVan – the only musical instrument I know of that got 8 miles a gallon downhill in a tailwind – played and ran for many years at Burning Man and various like-minded creative events and venues, and many thousands of people enjoyed playing on its instruments and generally making happy noise.

In 2019, with much excitement, we moved to New York City – which meant that, with much regret, I had to sell the vehicle, unmount all the instruments to put them into storage, and move on to a new phase in our lives together.

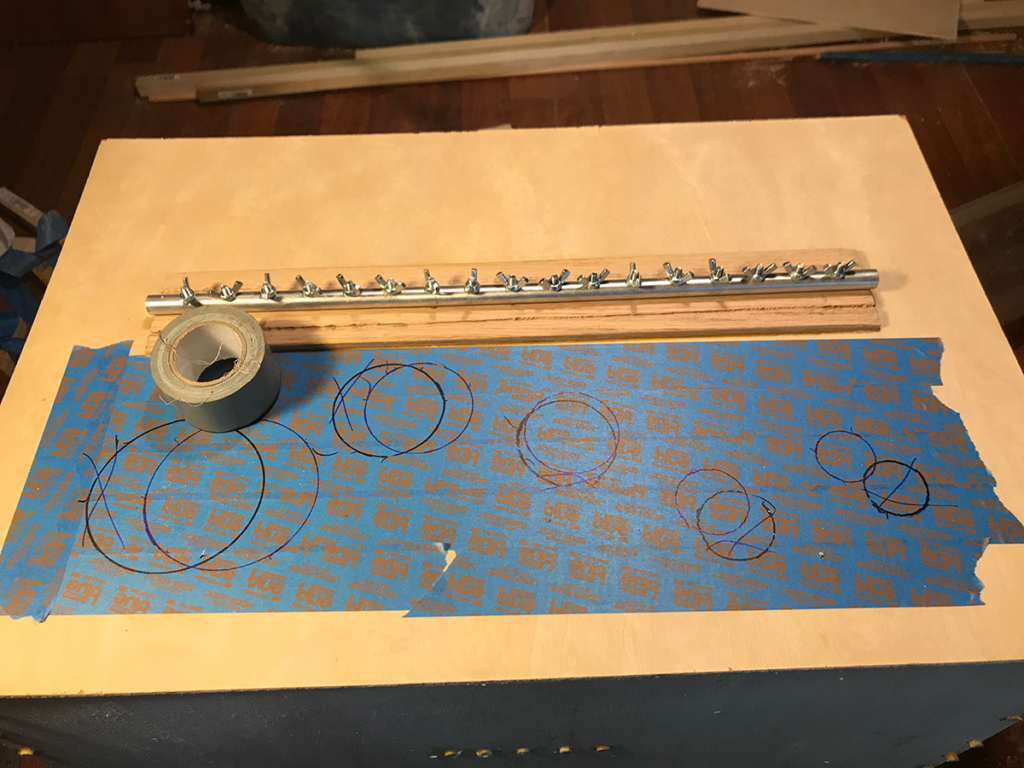

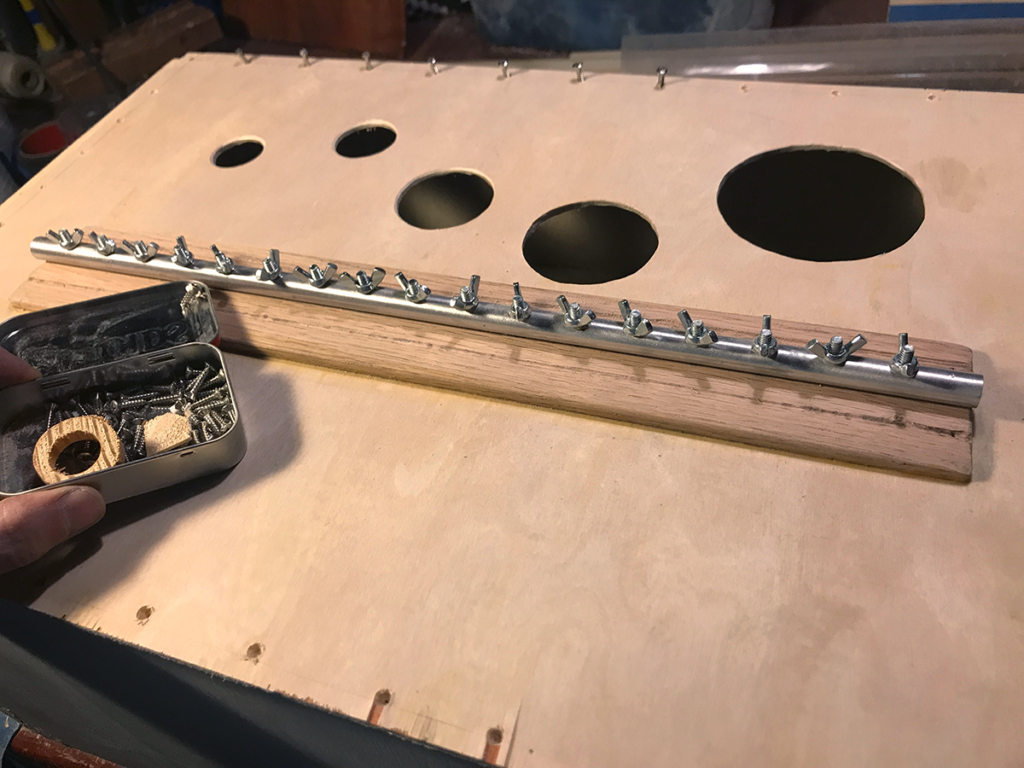

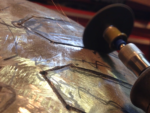

We moved to Seattle in 2021 and this year, I finally got tired of tripping over this set of scrap-aluminum gongs (which I had stripped off of the van and rearranged in this array four years earlier in a fit of creative frustration in NYC) and decided to share them with the world again.

So here they are, mounted on one of our flowering plum trees (carefully, so as not to hurt the tree!)

We’re also planning to bring the xylophones up from storage in L.A. and mount them in the front yard for all to play. In the meantime, you’re invited to come bang on the gongs. Please enjoy.

UPDATE: Confidential to the wonderful stranger who ding-dong-ditched a pair of Sonor percussion mallets on our front porch this week:

Thank you! I’ll rig them up and put them out so people can play together. Next time you’re around, please say hi!