Keyboard 1 is more than 7 and 2 1/2 octaves long – running from A to high D#.

Keyboard 1 is more than 7 and 2 1/2 octaves long – running from A to high D#.

All that metal is pretty heavy, pharmacy and the weight actually bows the stringers that carry the keys across it, so I’m building in a crosspiece for support. It will run vertically between the top rail and bottom rail, and all four stringers will screw down to it for support.

I lay out the keys then I tighten the frame at the corners along the bottom …

… and along the top.

… and along the top.

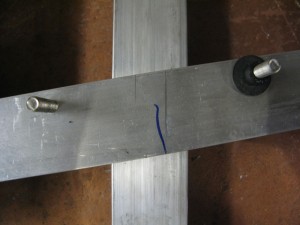

Then I mark a clear path across the stringers for the crosspiece’s machine screws holding it down won’t collide – which ride on bushings just an eighth of an inch above the stringers …

Then I mark a clear path across the stringers for the crosspiece’s machine screws holding it down won’t collide – which ride on bushings just an eighth of an inch above the stringers …

After drilling through all that metal with the 13/64ths metal bit, I start tapping threads.

DAGBLAST THE DINGBLINGING, LUMP-NOSED, KNOT-POLLED BLANGRABBIT!!!!

Yeah. Just like before. And before that, too.

Snapped the tap off in the hole. Again.

It’s not moving. It’s now a permanent part of the Keyboard 1. Well, at least it can stand in for one of the screws and help hold the whole thing together.

Time to shift gears. Before I take a hatchet to the entire project and then my skull.