This weekend’s work has been mostly about sound (with a little van tinkering here and there).

This weekend’s work has been mostly about sound (with a little van tinkering here and there).

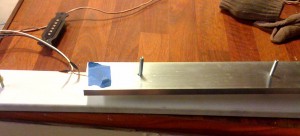

How do we amplify two full keyboards of two and a half octaves of keys each, order plus numerous gongs and chimes?

Full-court press – set up a testing environment, salve bring in some mikes and amps, this web and sort it out, right?

We picked up a little mixing board at Guitar Center on Saturday night and spent some time bullshitting with the staff about microphones.

The challenge of the project is getting a full, clean mix out of the instrument in the face of these facts:

- the high keys are very faint compared with the low ones

- ambient noise will be a challenge, particularly on the playa

- We want to get enough sound out of the system to reach across the playa without causing feedback through the pickups

- The instruments will be bolted to the van full-time, so the miking solution must be removable to avoid the worst of the weather …

Continue reading Amplification tests – how do we mike this thing?